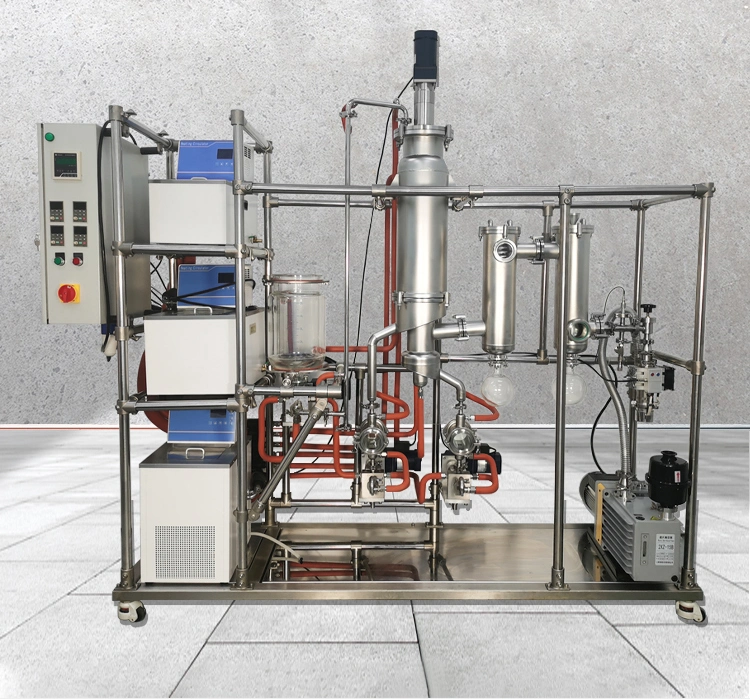

Wiped Film Evaporator Molecular Distillation Equipment

Overview wiped film evaporator molecular distillation equipment Product Description Wiped Film distillation is a special;

Overview

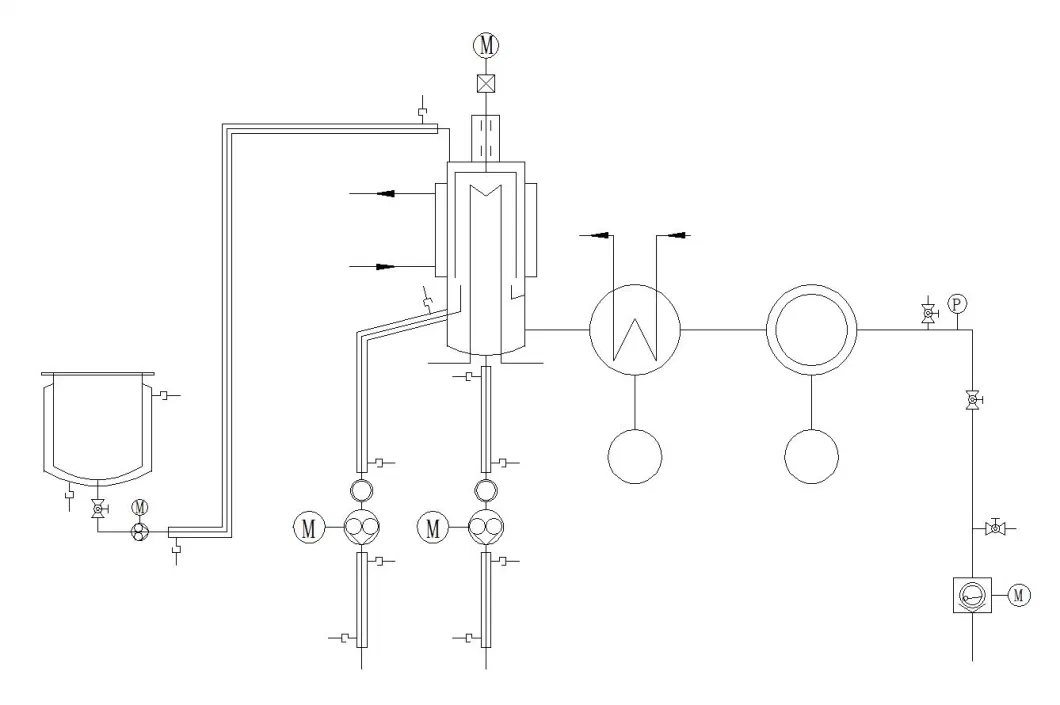

Wiped Film distillation is a special liquid-liquid separation technology, which is different from the traditional distillation based on the separation principle of material boiling point difference, but based on the difference in the mean free path of molecular motion of each material in the mixture to achieve separation.Structure Introduction

Certifications

Basic Info.

| Model NO. | FMD-2SS |

| Stainless Steel Material | 304/316 |

| Condensing Area | 4.9 M2 |

| Feeding Speed | 100-200 L/H |

| Effective Evaporator Area | 2 M2 |

| Transport Package | Wooden Box or Customized Packaging |

| Trademark | Lanphan |

| Origin | Henan, China |

| Production Capacity | 500 Units Per Month |

Product Description

wiped film evaporator molecular distillation equipmentProduct Description

Wiped Film distillation is a special liquid-liquid separation technology, which is different from the traditional distillation based on the separation principle of material boiling point difference, but based on the difference in the mean free path of molecular motion of each material in the mixture to achieve separation.Structure Introduction

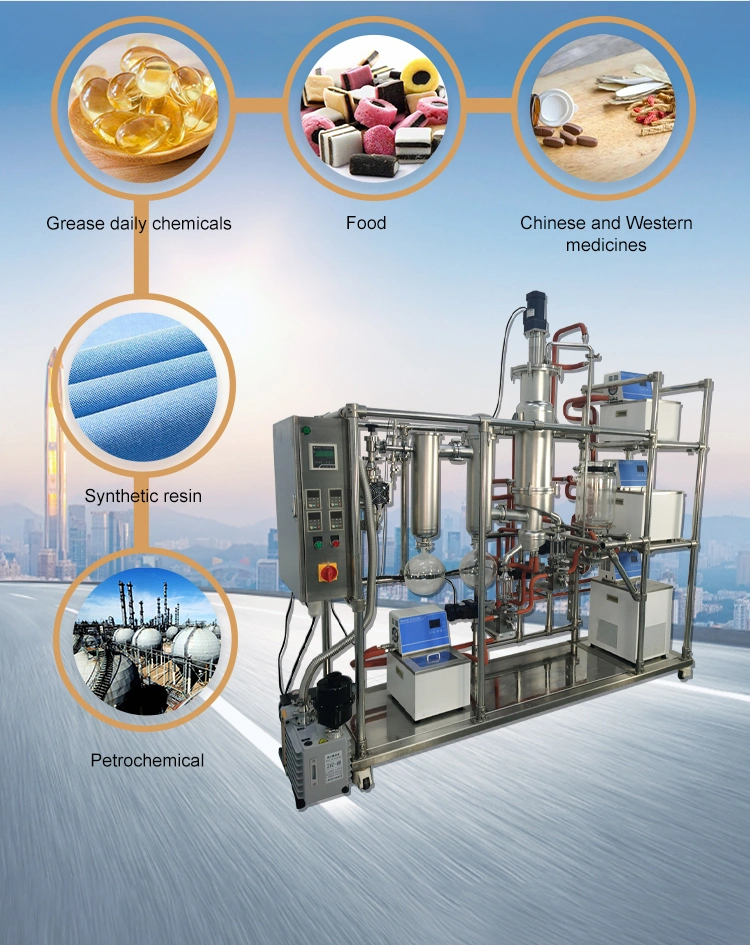

1. Thermal separation of heat-sensitive compounds.

2. Purification of organic synthetic substances.

3. Purification of active ingredients in biological extracts.

4. Recycling of industrial waste.

5. Removal of toxic substances in the food industry.

6. Odor removal of organic compounds

7. Thorough removal of residual solvents in the compound.

| Stainless Steel Molecular Distillation | ||||||||||

| Model | FMD-0.1SS | FMD-0.15SS | FMD-0.25SS | FMD-0.35SS | FMD-0.5SS | FMD-1SS | FMD-1.5SS | FMD-2SS | FMD-3SS | FMD-5SS |

| Effective evaporation area(m2) | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 | 1 | 1.5 | 2 | 3 | 5 |

| Condensing area(m2) | 0.17 | 0.3 | 0.4 | 0.7 | 1.7 | 2.7 | 3.5 | 4.9 | 6.5 | 8 |

| Feeding speed(L/H) | 5-12 | 6-15 | 10-25 | 15-30 | 20-60 | 50-120 | 60-180 | 100-200 | 100-300 | 200-500 |

| Rotate speed(r/min) | 30-350 | |||||||||

| Stainless steel material | 304/316 | |||||||||

| Feeding method | Gear pump automatic continuous feeding | |||||||||

| Discharge method | Gear pump automatic continuous discharge | |||||||||

| Operating Temperature(ºC) | Within 350ºC | |||||||||

| Voltage | 220V/60Hz Other voltages can be customized | |||||||||

You may also like

Send inquiry

Send now