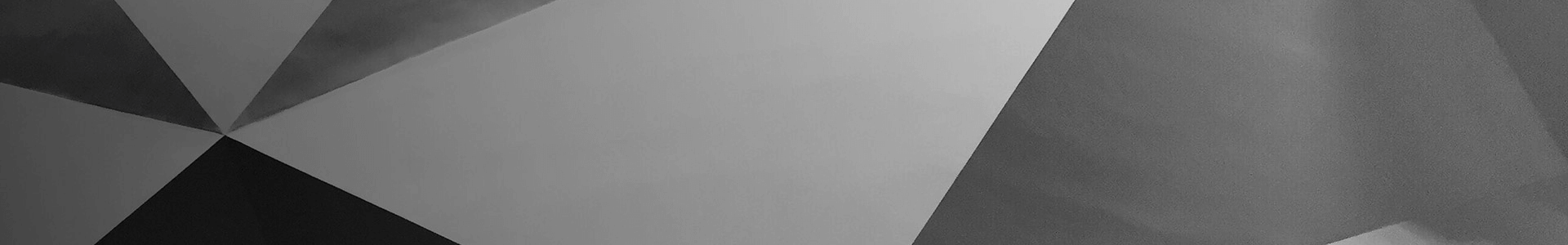

Stainless Steel Fully Welded Plate and Block Heat Exchanger for Oil Refinery Plant

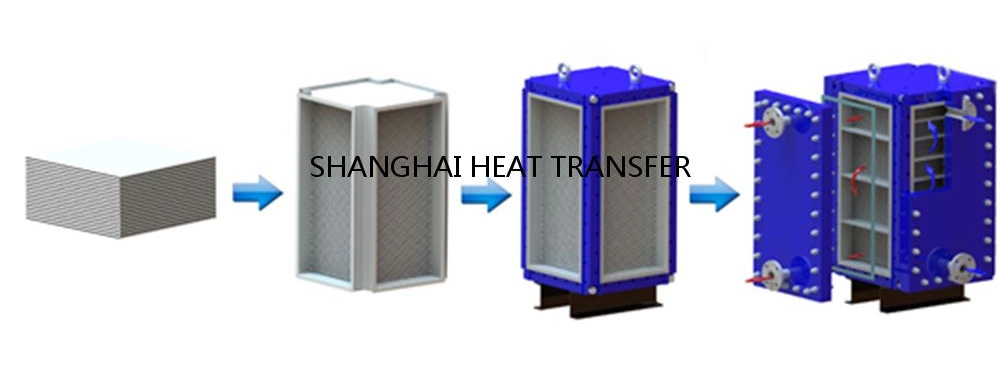

PRODUCT INTRODUCTIONHT-Bloc is made up of plate pack and frame. The plate pack is certain number of plates welded togeth;

Basic Info.

| Model NO. | HT |

| Material | Stainless Steel |

| Plate Thickness | 0.8~1.2 mm |

| Plate Material | 304L/316L/904L/254smo |

| Plate Spacing | 8~10 mm |

| Design Temperature | -20~350 Deg C |

| Design Pressure | Fv~3.2MPa |

| Transport Package | Wood |

| Specification | Max. 2000 square meter |

| Trademark | SHPHE |

| Origin | Shanghai, China |

| HS Code | 84195000 |

| Production Capacity | 1000 Pieces/Year |

Product Description

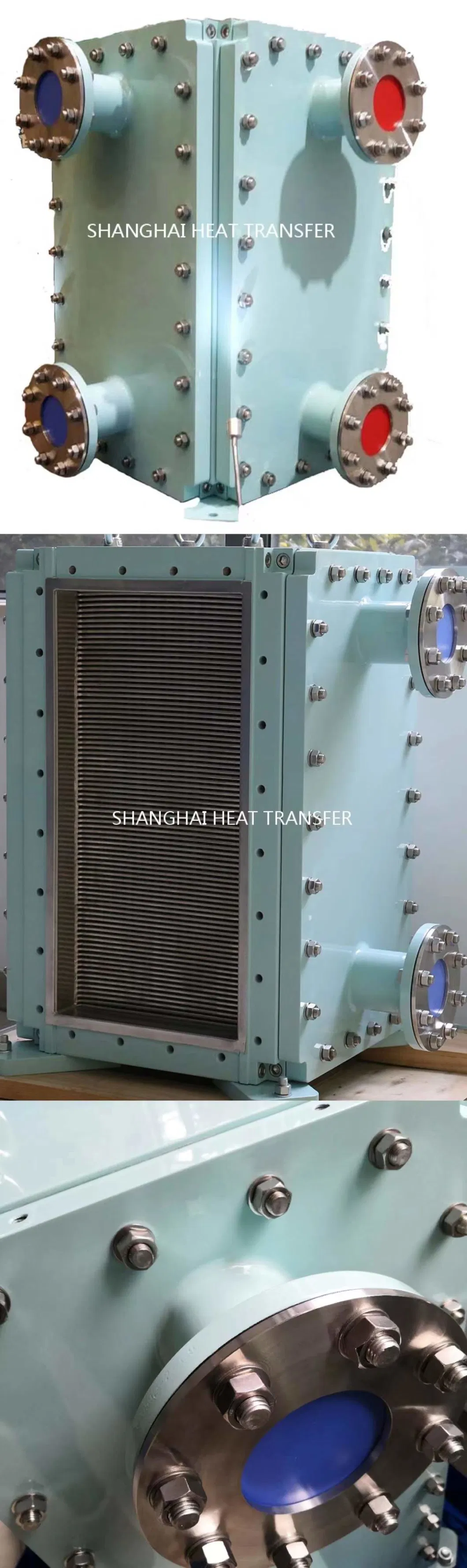

PRODUCT INTRODUCTIONHT-Bloc is made up of plate pack and frame. The plate pack is certain number of plates welded together to form channels, then it is installed into a frame, which is formed by four corner girders, top and bottom plates and four side panels. The frame is bolted connected and can be easily disassembled for service and cleaning. There are three different plate patterns, corrugated, studded, and dimpled pattern, to meet different process requirements.

WORKING PRINCIPLESThe cold and hot media flow alternately in welded channels between the plates. Each medium flows in a cross-flow arrangement within each pass. For multi-pass unit, the media flow in countercurrent. The flexible flow configuration makes both sides keeping the best thermal efficiency. And the flow configuration can be rearranged to fit the change of the flow rate or temperature in the new duty.

ADVANTAGES

The plate pack is fully welded without gasket;The frame can be disassembled for repair and cleaning;Compact structure , high thermal efficient and small footprint;The unique design of π angle TM prevent "dead zone ";The butt welding of plates avoid risk of crevice corrosion;The flexible flow configuration can ensure consistent high thermal efficiency;Short flow path fit low-pressure condensing duty and allow very low pressure drop.A variety of flow form meets all kinds of complex heat transfer process.

FEATURES

| Design Temperature/ºC | -20~350 |

| Design Pressure/MPa | FV~3.2 |

| Area/m2 | 1.4~860 |

| Plate Spacing/mm | 8~10 |

| Plate Thickness/mm | 0.8~1.2 |

| Model | BC20/BC40/BC60/BC75/BC120 |

| Plate Material | 304L,316L,904L,254SMO |

APPLICATIONS

1.Refinery Pre-heating of crude oilCondensation of gasoline, kerosene, diesel, etc.2.Natural gas Gas sweetening, decarburization --lean/rich solvent serviceGas dehydration -- heat recovery in TEG systems3.Refined oilCrude oil sweetening -- edible oil heat exchanger4.Coke over plantsAmmonia liquor scrubber coolingBenzoilzed oil heating, cooling5.Refine sugarMixed juice, fumigated juice heatingPressure mooring juice heating6.Pulp and paperHeat recovery of boil and fumigationHeat recovery of bleaching processWashing liquid heating7. Fuel ethanolLees liquid to fermented liquid heat exchangePre-heating of ethanol solution8.Specialty chemicals, Metallurgy, Fertilizer production, Chemical fiber, Water treatment plant, etc.

CUSTOMERS AND REFERENCE

You may also like

Send inquiry

Send now