Shell and Tube Heat Exchanger for Petroleum and Petrochemical Industry

Overview Product Description 1,The main components of shell-and-tube heat exchanger include shell, tube bundle and tube ;

Overview

Basic Info.

| Model NO. | AM19-BEU-10/30-5000 |

| Delivery Details | Within 30 Days of Order Generation |

| Design Standard | Nb/T47004.1-2017 |

| Maximum Aperture | 20 Inches. |

| Heat Exchange Capacity | 0.05-300MW |

| Pressure Range | Vacuums-10MPa |

| Standard Tempera | -40ºC-500ºC |

| Shell Material | Carbon Steel 304 316L |

| Heat Exchange Tube Material | 304 316L Ta1 |

| Transport Package | Customized on Request |

| Specification | Customized on request |

| Trademark | Ametech |

| Origin | Shanghai-China Jiangsu-China |

| HS Code | 8419500090 |

| Production Capacity | 10000 Units/Year |

Product Description

Product Description

1,The main components of shell-and-tube heat exchanger include shell, tube bundle and tube plate. The shell is usually cylindrical, with a number of tubes installed inside, and the tubes are fixed by parallel tubes through the tube plate.2,Shell and tube heat exchangers transfer heat through the fluid in the shell path in the shell and the tube path in the inner tube bundle. Heat can be transferred between shell and tube by conduction and convection.3,The design of shell-and-tube heat exchanger makes the heat transfer area large, and at the same time realizes the efficient heat transfer through the flow of fluid.4,To adapt to large flow and high pressure conditions. By increasing the number of tube bundle, adjusting the diameter and length of pipe and other parameters, the requirements of different process conditions can be met.5,Shell and tube heat exchangers can handle high temperature, high pressure and corrosive media.6,Shell-and-tube heat exchangers are relatively easy to maintain and clean. By removing the tube plate, the internal tube bundle can be easily inspected, cleaned or repaired.Product Parameters

| Serial number | Correlation parameter | Min | Max |

| 1 | Design pressure | FV | 10MPa |

| 2 | Test pressure | FV | 13MPa |

| 3 | Design temperature | -40ºC | 500ºC |

| 4 | Flow range | 1m³/h | 3000m³/h |

| 5 | Heat transfer area | 1sq.m | 3000sq.m |

| 6 | Heat exchange capacity | 50KW | 300MW |

Detailed Photos

Company Profile

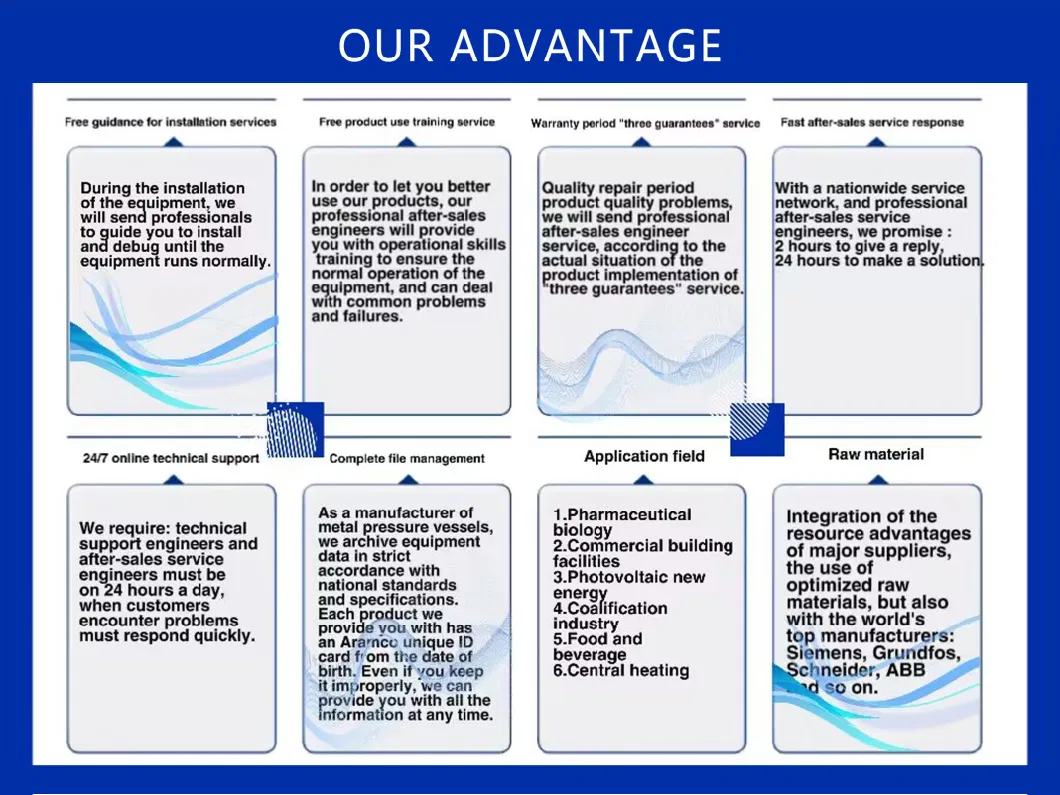

Our Advantages

FAQ

You may also like

Send inquiry

Send now